Where are your brand’s emissions hiding?

The overlooked stages driving fashion’s footprint

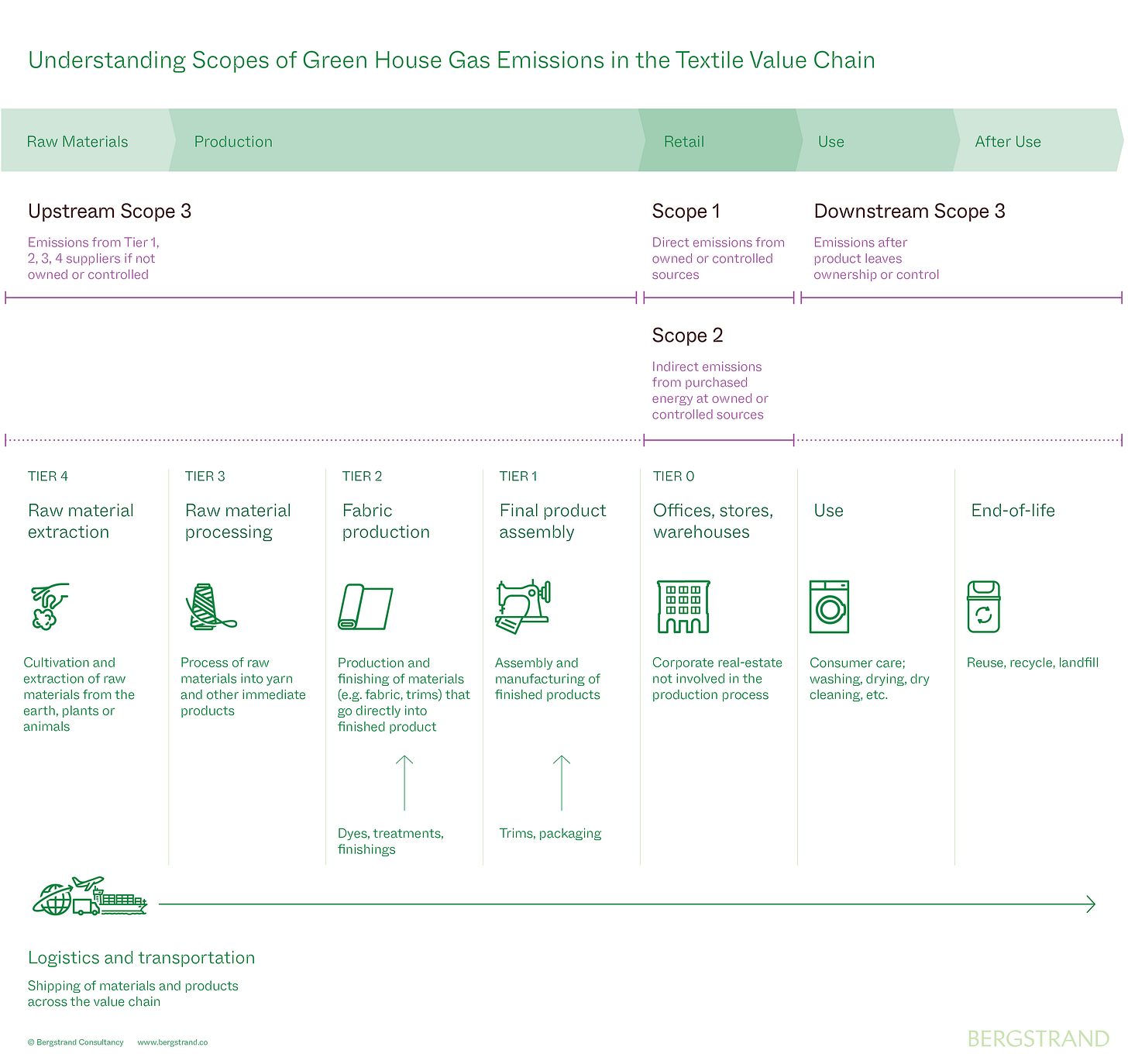

For most fashion and textile brands, over 90% of emissions sit in Scope 3, the parts of the value chain that brands don’t directly control. That means even if every office switches to LED lights and every store runs on renewable power, the real footprint remains elsewhere.

It’s in Tier 4 fields where fibres are grown, Tier 2 dye houses and mills where fabrics are finished, the ships and planes that move garments, and even in customers’ laundry rooms.

This newsletter shines a light on those hiding places, from raw materials to end-of-life, and why ignoring them is no longer an option.

The First Hiding Place is Raw Materials

The story begins long before a garment reaches a factory. Raw material production, from cotton fields to wool farms to polyester production facilities, is where emissions are often “baked in.”

For natural fibres, agricultural emissions come from synthetic fertiliser use, irrigation, diesel-powered machinery, and, in the case of animal fibres, enteric methane from livestock. For synthetics, the picture is even more stark: polyester is essentially oil in another form, and its production draws heavily on fossil feedstocks, petrochemical processing, and grid electricity in coal-reliant regions.

This means that no matter how “green” a brand’s store or sewing factories (Tier 1) are, a big portion of emissions is already locked in at the fibre stage, often before you’ve placed your first purchase order.

Procurement strategies should prioritise fibres with lower cradle-to-gate footprints (e.g. recycled, regenerative, closed-loop), but should also consider region-specific impacts and supplier energy sources. The choice of farm or producer can be as significant as the choice of fibre.

The Carbon Giant in the Middle: Fabric Processing and Dyeing

If raw materials are the first footprint, fabric processing is the carbon giant lurking in the middle.

Spinning fibres, weaving or knitting, dyeing, and finishing are energy- and chemical-intensive processes. In Asia, where much of the world’s textiles are made, mills often rely on coal-fired boilers to produce the heat and steam needed for dyeing.

This is also where visibility typically breaks down. Many brands know their Tier 1 suppliers (sewing factories), but they are still far away from the fabric mills that supply those factories. Without traceability and data-sharing, emissions at this stage remain invisible.

But ignoring these stages is a mistake. Switching to low-impact processing technologies like waterless dyeing or laser finishing can cut emissions significantly. While some changes, like moving boilers off coal, are often outside suppliers’ control in countries such as China, where the government decides the energy mix, brands can still support progress.

Many currently buy green certificates to offset this, but these don’t drive the real change needed. As advocacy groups have pointed out to brands like Lululemon, if Asian suppliers don’t move off coal by 2030, climate targets won’t hold. The question remains: who will finance this transition, suppliers already operating on thin margins, or the brands that rely on them?

Tier 1 is the Visible but Smaller Slice

Cut-and-sew factories are where most brands have direct relationships, and where many sustainability strategies have traditionally focused. Yet, compared to Tiers 2, 3 or 4, their direct emissions are modest. Sewing machines and irons are electricity-driven and labour-intensive rather than energy-hungry.

That doesn’t mean this stage should be ignored. Fast fashion’s fragmented, short-term sourcing models discourage factories from investing in efficiency upgrades. Longer-term partnerships, co-financed energy improvements, or even solar panels on factory roofs can reduce emissions while strengthening supplier relations. For brands with higher-end or regionalised production, cleaner grids in places like Portugal or Türkiye can be an advantage. Outside Europe, countries like India, Vietnam, and Sri Lanka are also scaling up renewables.

The Hidden Bomb of Air Freight

Fashion is global: fabrics are often produced or sourced in countries like China, garments are manufactured in hubs such as Bangladesh, and finished products are shipped to regions like Europe for distribution worldwide.

Emissions from transport and logistics depend not only on distance, but mode.

Sea freight is efficient. Air freight is not. Yet many brands still fly in goods to meet drop dates or replenish bestsellers. Moving one ton of goods by air can emit 50–60 times more CO₂ per kilometre than by sea.

The surge of e-commerce adds another layer: returns. In Europe, around 20% of online clothing purchases are sent back. In the fast fashion and low-cost segment, many of these returns are destroyed rather than resold, which doubles the footprint of logistics and creates avoidable waste.

Better options exist: such as shifting to rail freight as a middle ground, designing supply chains to avoid back-and-forth zigzags, and discouraging over-reliance on air freight through smarter inventory planning. But these are not quick fixes: tight lead times, delays, and cost pressures make them hard to put into practice.

Tackling logistics emissions often means rethinking planning cycles and accepting longer lead times, a challenge for many brands.

Consumer Use and End-of-Life

Post-sale, emissions don’t stop. In fact, the use phase, especially laundering and drying, can represent a significant share of lifetime impact for basics and sportswear.

Brands can help by promoting cold-water washing, line drying, and extending garment lifespans through repair services and higher-quality design. Longer life means lower emissions per wear.

End-of-life is another overlooked stage. Today, most clothing ends up in landfills or incineration, releasing carbon all over again. Worse, 4–9% of textiles in Europe are destroyed before they're even worn. Designing for recyclability, supporting take-back schemes, and partnering with fibre-to-fibre recyclers can keep clothes in circulation.

How to Find and Tackle Hidden Emissions

Tools exist to find and measure these hidden hotspots:

GHG Protocol provides a standardised framework for tracking Scope 1, 2, and 3 emissions (covering direct operations, purchased energy, and value chain impacts)

Life Cycle Assessments show stage-by-stage footprints

Science-Based Targets align reduction goals with climate science

Traceability platforms and carbon management software are helping brands map beyond Tier 1

Industry collaborations like the Apparel Impact Institute and STICA are pooling resources for decarbonisation

Regulation is coming too. In the EU, the Corporate Sustainability Reporting Directive and Product Environmental Footprint (PEF)-based labelling are making robust emissions data a legal requirement.

Real-World Momentum Worth Watching

Manufacturers showing the way: In Pakistan, Sapphire Finishing Mills has nearly eliminated coal-powered dyeing using biomass boiler technology. In India’s Odisha mega‑park, Epic Group is building near‑net zero factories powered by rooftop/off‑site solar and biomass boilers

Circular polyester and cotton is scaling: U.S.-based recycler Circ is setting up the first large-scale facility for polycotton recycling in Saint-Avold, France. The project is supported by investors, including Inditex, Patagonia’s backers, and Breakthrough Energy Ventures

Emissions are unfortunately rising: 2024 was the warmest year on record, and in 2023, the fashion and textile sector emissions increased 7.5 per cent from the previous year. The Apparel Impact Institute attributes this to the growth in garment production and polyester fibre usage

Final Thoughts

From cotton fields to customer wardrobes, emissions hide across fashion’s value chain. For a long time, brands have focused on the parts they can see, stores, warehouses, and Tier 1 factories, while the real footprint lies elsewhere.

The key question isn’t whether your brand has hidden emissions. It’s: Do you know where they are, and what you’re going to do about them?

Bergstrand helps brands uncover their hidden footprint and create a roadmap to reduction.

➾ Discover how we can audit and recommendation CO₂-emission calculation platforms for your brand.

Or if you’re ready to uncover your brand’s emissions, get in touch: info(at)bergstrand.co

Photo credits: Meddy Huduti, Bergstrand, Vasyl S.